itemis ANALYZE is our preferred traceability tool that helps us create comprehensive, analyzable and visualizable trace information covering our entire toolchain for releases, features, requirements and architecture elements in different tools. In addition, the integrated full-text search for all artifacts in our tools is very helpful.

Read how the automotive supplier KOSTAL finalizes their ASPICE assessment successfully with itemis ANALYZE.

Traceability Throughout Product Life Cycles

Compliance With Industry Standards

Perform your functional safety analysis with itemis ANALYZE to become compliant with industry standards like ISO 26262 or ASPICE.

Insightful Decision Making

Provide practitioners access to information related to the requirements and connected artifacts for informed decision-making.

Close Artifact Gaps

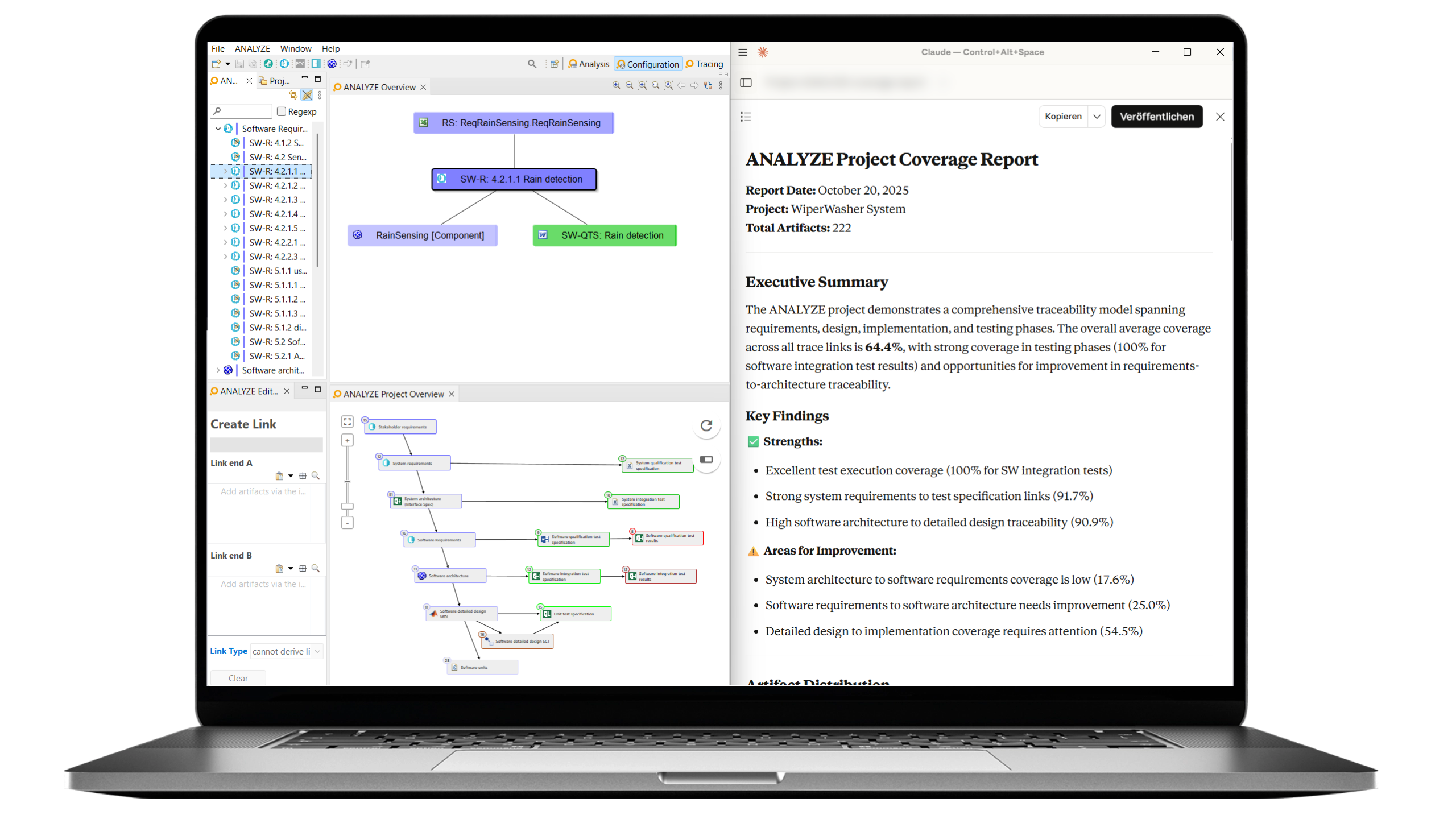

Help project managers identify and close traceability gaps to ensure full coverage across requirements, design, development, and test.

Improved Product Quality

Optimized processes result in improved product quality as well as faster product development and time to market.

Complete Life Cycle Traceability

Many companies claim that their solution enables the creation of complete life cycle traceability, but only itemis ANALYZE can actually deliver that promise.

Single Source of Truth

Avoid fragmentation of traceability in heterogeneous toolchains and bring all project data together to single source of truth.

AI Enabled Product Engineering

Standardised Interface (MCP)

Connecting the engineering context via the Model Context Protocol (MCP), which serves as a standardised interface for LLMs.

Consolidation In Heterogeneous Landscapes

Creating a comprehensive Knowledge Graph across the entire engineering landscape and ensuring data reliability by reducing the LLM's fuzziness by formalizing LLM results into the itemis ANALYZE query language.

Automation Of Compliance And Audits

Using AI with itemis ANALYZE reduces the effort required for engineers to demonstrate and monitor compliance.

AI-Supported Verification And Compliance Completion

Acting as a "smart assistant" to support Quality Assurance (QA) and Safety Engineering by analyzing the existing traceability structure.

Engineering Context For Arbitrary LLMs

itemis ANALYZE is ensuring Large Language Models (LLMs) can perform meaningful work, the provision of engineering context - including data like requirements, system architectures, or source code in a usable form - is crucial, particularly when users lack access to this data.

AI-Supported Agentic Workflows

By allowing the AI to fetch the missing context itself, it can autonomously develop necessary solution approaches and ideas, significantly reducing the time and effort required for the human user.

Customer Success

KOSTAL

Kostal is a 1-tier Automotive supplier and thus has to comply with certain process and security standards. In order to comply with Automotive SPICE Level 3, Kostal was searching for a solution to fulfill the respective requirements traceability obligations.

DENSO

In order to meet European standards and market requirements, DENSO Germany had specified a development process to be implemented in an integrated tool chain. The goal was to ensure traceability throughout the development process and thus create more transparency from requirements through to code.

Further Information

Get Your Free Product Demo Now

Our experts are pleased to answer further questions about itemis ANALYZE - free of charge and without obligation.

We look forward to your request!