The customer

BLG LOGISTICS is a seaport and logistics service provider with an international network and a corporate history spanning more than 140 years. Today, the company is present in all of the world's growth markets with more than 100 locations and branches in Europe, America, Africa and Asia. BLG LOGISTICS offers its customers, from industry and trade, comprehensive logistics system services.

Initial situation and challenge

BLG LOGISTICS operates a transhipment centre for motor vehicles at the Port of Hamburg. Vehicles are repaired and prepared in various halls there. When a vehicle enters or leaves the hall, the hall doors are opened and closed manually by the driver using a cable (from the outside) or by pressing a button (from the inside). Some of the 20 doors, from different manufacturers, can only be operated via an internal switch.

After entering the hall, the chassis number of the vehicle is manually read into the merchandise management system.

The entry and exit of the vehicles as well as their registration is very cumbersome and time-consuming. Getting in and out of the vehicle is a burden on the staff. The gates stand open unnecessarily. This causes high heating losses in the winter months.

A smart "upgrade" of the roller shutter doors was desired. It should no longer be possible to control them only manually, but also automatically. The challenge was to develop a solution that was as simple and cost-effective as possible. It had to work with the different door systems, as replacing the door drives was out of the question for cost reasons.

Approach and solution on the part of itemis

The "intelligent roller shutter" is an IoT prototype developed as part of an innovation project. It can be integrated non-invasively into existing manual controls of electrically driven roller doors. This prototype is the perfect basis for solving the BLG LOGISTICS challenge, taking all requirements into account.

Implementation

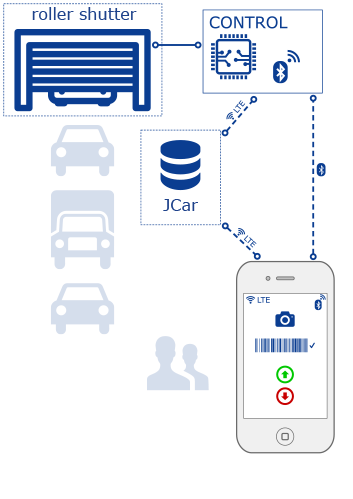

We decided to equip the roller shutters with a microcontroller-based control system. This can be accessed and controlled via Bluetooth and WLAN from a mobile application (native Android app) via smartphone.

The operating procedure is as follows:

- A unique code is placed in the interior of each vehicle. This is recorded by the driver using a mobile app.

- The data is synchronised with a web service. As soon as the mobile phone is near the gate, it opens automatically.

- The gate itself uses a web service to record which car passed the gate at what time and how long the gate was open.

- Via another web service, the vehicle can be automatically booked into the merchandise management system.

Of course, the gate can still be controlled manually by cable and button, as well as via the app on the smartphone. All configuration parameters are stored in the cloud and can be quickly and easily adjusted during operation.

Customer advantage / customer benefit

The intelligent roller shutter door control, with connection to the cloud, now opens the door automatically as soon as authorised vehicles approach. This speeds up the process, as the employee no longer has to get out to open the gate manually.

In addition to making life easier for the workforce, the IoT system can reduce heating costs by keeping the gates open only as long as necessary. The seasons can be optimally taken into account with the developed IoT solution. A lock operation can be used to ensure that opposite gates are not open at the same time in winter. This prevents unpleasant draughts in the often very windy port of Hamburg. In summer, on the other hand, the gates can remain open to cool down.

In addition to the convenience functions, the intelligent gates enable real-time monitoring of vehicles entering or leaving the hall. With the help of asset management, the managers of BLG LOGISTICS gain a very precise insight into the processes and can track the path of the vehicles exactly.